Subtitles & vocabulary

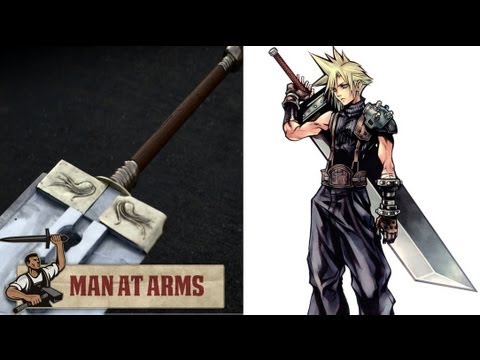

Cloud's Buster Sword (Final Fantasy VII) - MAN AT ARMS

00

VoiceTube posted on 2013/10/01Save

Video vocabulary

subscribe

US /səbˈskraɪb/

・

UK /səb'skraɪb/

- Verb (Transitive/Intransitive)

- To regularly pay to receive a service

B1TOEIC

More absolutely

US /ˈæbsəˌlutli, ˌæbsəˈlutli/

・

UK /ˈæbsəlu:tli/

- Adverb

- Completely; totally; very

- Considered independently and without relation to other things; viewed abstractly; as, quantity absolutely considered.

A2

More ridiculous

US /rɪˈdɪkjələs/

・

UK /rɪˈdɪkjələs/

- Adjective

- Funny or foolish; deserving to be laughed at

A2

More technique

US /tɛkˈnik/

・

UK /tekˈni:k/

- Noun (Countable/Uncountable)

- Way of doing by using special knowledge or skill

- The skill or ability to do something well.

A2TOEIC

More Use Energy

Unlock Vocabulary

Unlock pronunciation, explanations, and filters