Subtitles & vocabulary

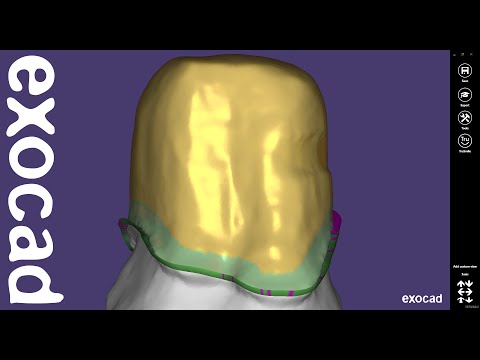

exocad Quick Guide: Crown Bottoms

00

徐隱 posted on 2016/12/04Save

Video vocabulary

individual

US /ˌɪndəˈvɪdʒuəl/

・

UK /ˌɪndɪˈvɪdʒuəl/

- Countable Noun

- Single person, looked at separately from others

- A single thing or item, especially when part of a set or group.

- Adjective

- Made for use by one single person

- Having a distinct manner different from others

A2

More material

US /məˈtɪriəl/

・

UK /məˈtɪəriəl/

- Noun (Countable/Uncountable)

- Cloth; fabric

- Supplies or data needed to do a certain thing

- Adjective

- Relevant; (of evidence) important or significant

- Belonging to the world of physical things

A2

More scale

US /skel/

・

UK /skeɪl/

- Noun (Countable/Uncountable)

- Size, level, or amount when compared

- Small hard plates that cover the body of fish

- Verb (Transitive/Intransitive)

- To change the size of but keep the proportions

- To climb something large (e.g. a mountain)

A2TOEIC

More negative

US /ˈnɛɡətɪv/

・

UK /'neɡətɪv/

- Noun

- The opposite to a positive electrical charge

- In grammar, containing words such as 'no' or 'not'

- Adjective

- Being harmful, unwanted or unhelpful

- In mathematics, being less than zero

A2

More Use Energy

Unlock Vocabulary

Unlock pronunciation, explanations, and filters