Subtitles & vocabulary

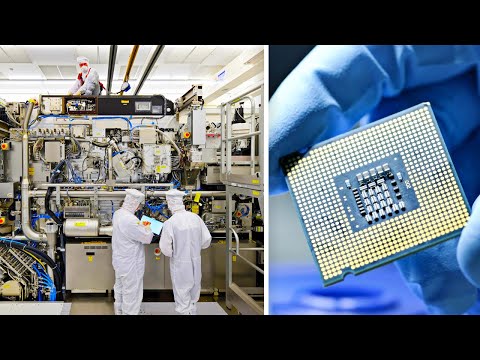

Inside The World's Largest Chips Factory

00

joey joey posted on 2021/08/04Save

Video vocabulary

process

US /ˈprɑsˌɛs, ˈproˌsɛs/

・

UK /prə'ses/

- Transitive Verb

- To organize and use data in a computer

- To deal with official forms in the way required

- Noun (Countable/Uncountable)

- Dealing with official forms in the way required

- Set of changes that occur slowly and naturally

A2TOEIC

More material

US /məˈtɪriəl/

・

UK /məˈtɪəriəl/

- Noun (Countable/Uncountable)

- Cloth; fabric

- Supplies or data needed to do a certain thing

- Adjective

- Relevant; (of evidence) important or significant

- Belonging to the world of physical things

A2

More effort

US /ˈɛfət/

・

UK /ˈefət/

- Uncountable Noun

- Amount of work used trying to do something

- A conscious exertion of power; a try.

A2TOEIC

More basically

US /ˈbesɪkəli,-kli/

・

UK /ˈbeɪsɪkli/

- Adverb

- Used before you explain something simply, clearly

- In essence; when you consider the most important aspects of something.

A2

More Use Energy

Unlock Vocabulary

Unlock pronunciation, explanations, and filters